The FAQs about Proofs and Proofing

How colour accurate is a proof from Proofing.de?

A proof from https://shop.proof.de is produced in accordance with the currently valid ISO standard 12647-7 and is colour-binding and legally binding with UGRA-Fogra media wedge and test report.

Proof.de works exclusively with Epson proofing devices that are equipped with the latest X-Rite Spectroproofer-ILS30 measuring devices and measure and check proofs in the device directly after printing.

How does that work?

How does that work?

When you order a proof with UGRA/Fogra Media Wedge CMYK V3.0 from proof.de, the media wedge is printed with its 72 standardised colour fields directly below your proof. This media wedge is then actively dried directly in the proofing device and then measured by a Spectroproofer measuring device. The measured values thus determined are evaluated by the proof server. If the measured colour values are within the tolerances of the ISO standard, then a test report of the measurement is printed directly behind the media wedge, which guarantees you the colour accuracy according to ISO 12647-7 (see picture below). As you can see in the picture below, our proofs are usually well below the limits permitted within the standard.

The automated creation and testing of the media wedge directly in the proofer has many advantages:

- The measurement takes place automatically directly after the proof printing, measurement errors due to manual operating errors are excluded. Since the test report is not “glued on” afterwards, as is still common practice, manipulation is also impossible.

- Using the same measuring device integrated in the proofer, the proof printer calibrates itself at regular intervals and thus guarantees perfect proof results.

- We have the proof system with the most precise colour reproduction on the entire printer market (commissioning in 2016, software from 2017). This enables us to proof not only the classic CMYK colour spaces, but also Pantone and HKS colours, which would otherwise often be pale and not really close to the original. Over 99% of all Pantone colours can be represented by our proofing system.

Further information on the proof protocol, the media wedge as well as the work and responsibility of UGRA/Fogra can be found at www.ugra.ch and www.fogra.org.

What proofing papers are proofs printed on?

We use the EFI Gravure Proof Paper 4245 with 245g / sqm for the simulation of brightener-free coated printing papers (e.g., ISOCoatedV2). It’s touch is of very high-quality, and is also perfect for presentations at the customer.

We use the EFI 8245 OBA with 245g/sqm for the simulation of OBA / brightener-containing coated papers (for example, PSOcoatedV3). In contrast to the Gravure Proof Paper, the paper white of the OBA paper is significantly more blueish.

If you need a proof for brightener-free uncoated papers (for example PSOuncoated), we offer a proof on matte EFI 9120 XF 120g / sqm proofing paper. It is very good for the simulation of uncoated papers, since it is very similar in haptic and thickness to a stationery paper.

If you need a proof for OBA/brightener-containing uncoated papers (for example PSOuncoatedV3), we offer a proof on matt EFI 8175OBAmatte proofing paper with 170 / sqm. It contains a high amount of optical brighteners and is therefore very similar to a modern, brightwhite preprint or office paper.

| EFI 4245 Gravure Proof Paper | EFI 8245 OBA Semimatte | EFI 9120 XF matte | EFI 8175OBA matte | |

|---|---|---|---|---|

| weight: | 245 gr/qm | 245 gr/qm | 120 gr/qm | 175 gr/qm |

| strength: | 260 µ | 245 µm | 150 µm | 230 µm |

| opacity: | 96% | > 95% | 95 % | 97% |

| gloss (Tappi 75°) | 54 % (satinglossy) | 22 % (semimatte) | 6 % (matte) | 5% (matte) |

| L*a*b paperwhite | 94,5 / 0,0 / -1,5 | M0: 95,8 / 0,9 / -4,3 M1: 96,0 / 1,1 / -5,6 |

96,7 / 0,2 / -2,4 | M0: 96,8 / 2,5 / -7,7 M1: 97 / 3,0 / -10,8 |

| Data Sheet | data sheet EFI 4245 | data sheet EFI 8245 | data sheet EFI 9120 | data sheet EFI 8175 |

Further information about our certified proof papers can be found here.

I print with flyeralarm.de or other large European online printers – Why should I proof at Proof.de?

Many printers are process standard offset printing certified (PSO) and print according to ISO

12647-2. This is the same ISO standard, after which we create our proofs. Proof and the printing fit perfectly together.

Partially, you can also have a digital proof made at online printing companies – but only within the scope of the actual order, not in advance. Flyeralarm does not offer any proofs in advance. In addition, these proofs – depending on the format – are not quite cheap. And, for example, flyeralarm.de does not offer any proofs for brochures.

With proof.de, you can create digital proofs to show your customer the printed result in advance – at every stage of the design process. And if your customer has taken the proof.de proof, then you can send the data to flyeralarm.de or other print portals. If these print offset printing according to the process standard, Proof and print should be very close to each other.

What ist the UGRA/Fogra Media Wedge? And: Do I need it on every single proof?

We are happy to deliver your proof with the latest UGRA / Fogra Mediawedge CMYK V3.0 with Measurement Protocol according to ISO/DIS 12647-7:2016 or the IDEAlliance Media Wedge. These media wedges are world standards for colourprecise proofing. In order to be able to prove that your proof, which you have delivered to the printing company, meets these standards, the media wedge is measured and the values analysed in case of doubt – i.e. in case of dispute or uncertainty. If the media wedge is “OK” and the measured values are within the tolerance, then the print shop must also achieve these values.

Your options:

- without Media Wedge

- one Media Wedge per page (plus € 2,- / page)

- one Media Wedge with Measuring Protocol per page (plus € 4,- / page)

- one Media Wedge with Measuring Protocol over all (plus € 4,- / order)

You can order your media wedges directly while choosing the article. If you would like to order one media wedge over all, please choose this article in addition to your proofs.

Practice shows:

If you proof and print an 8-page image brochure, it is usually sufficient to put the 8 pages together on the print sheet and on the proof and to print a media wedge after the last page. If the media wedge is provided with a measuring protocol, then it is directly “OK” and thus colour and legally binding. Strictly speaking, this then only applies to the last page, but experience shows that the printer would find it difficult to prove here that the proof of page 5 is not “OK”.

Strictly speaking, a media wedge must be placed on each proof page, but the measuring protocol is not required. So if you want to be on the safe side or have had problems with the printer in the past, then you should have either a media wedge or a media wedge with a measuring protocol created for each printed page. These media wedges are not cut off, but are printed directly together with the check log and the document on one sheet. So if you order a DIN A4 proof with media wedge and measuring protocol, the wedge and the protocol will be added to your A4 document. You will therefore receive a sheet in the format 31 x 31 cm back. Your DIN A4 page format will never be trimmed, but the measuring protocol and the media wedge will be printed next to it, thus extending the page size by these elements. In addition, a job ticket is also printed, which contains all important information about the proof system, profiles, rendering intents, proof software, etc

What is the best light for assessing proofs?

In order for you to be able to judge the colourfulness of a proof, you need a standardized lighting environment: Even if the identical proof is on the table at your agency in Hamburg and at the client’s in Munich at the same time, the light at a north window facing the Alster on a cloudy day is not the same as the light that prevails at the exact same time in Munich at a south window with a view of the Isar river when the sun is shining: Our Munich and Hamburg colleagues are discussing at the same time on the phone about completely different colours.

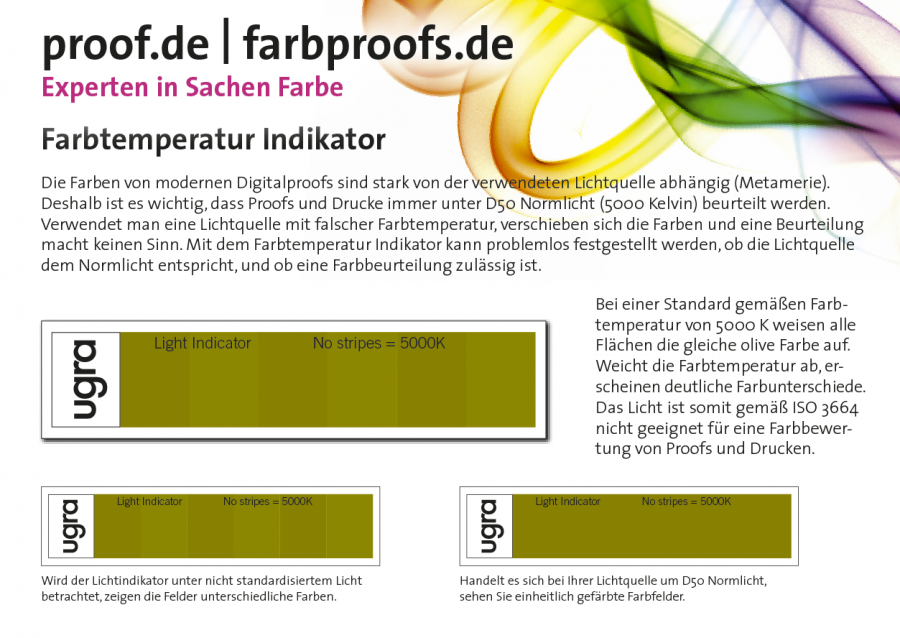

Therefore, only standardized artificial light can be used for colour matching. Colour matching must take place under the same light under which the proof is matched to the production run in offset: D50 standard light. This is light with a light temperature of 5,000 Kelvin and a defined, uniform spectral profile that optimally represents the colours.

Colour matching must take place under the same light under which the proof is matched to the production run in offset: D50 standard light. This is light with a light temperature of 5,000 Kelvin and a defined, uniform spectral profile that optimally represents the colours.

After all, the differences between a light bulb, a neon tube, a halogen lamp and a daylight LED as a possible light source are enormous. In addition, a new lighting standard has been in effect since 2009: ISO 3664:2009, which defines what the new D50 standard light looks like under which proofs and print products are matched to each other. And there is one innovation that catches the eye during the proofing process: the new standard light contains UV components that address the optical brighteners that are frequently used in offset papers. This was not the case until then.

With our Proof.de Metamerism Card you can see whether the light source corresponds to the standard light and if an assessment of the colour is permissible.

Also of interest:

An article about the issues of the new ISO 3664:2009 on Proofing.de

What is a contract proof? And what a form proof? What a validation print?

A contract proof according to ISO 12647-7 serves primarily to simulate the colour of the later printing process. The UGRA/Fogra Mediawedge CMYK V3.0 is used to control this liability. On the contract-proof, more information such as simulation profile, date and time, and much more are printed in a job ticket. In order to verify the colour compatibility, the media wedge is measured according to the proofing standard and a test certificate is printed which shows that the measured values are within the tolerance of the ISO 12647-7. If this is the case, the contract proof is considered to be colour accurate and legally binding – acting as a “contract” between designer and printing house.

A form proof is created to verify a layout or collection form for completeness. Also the correct imposition of the pages is checked on the formproof. The formproof is mostly printed on cheap paper and in poor quality, because only the stand is to be controlled.

A validation print according to ISO 12647-8 is a print with nearly accurate colours. A validation print is usually produced on a laser printer digital printing system. In contrast to the “contract proof” it is normally rasterized, much more “uneven” in the printed image, especially in colour swatches and gradients, and is measured with visibly higher tolerances. As a result, it is not legally binding as the real “contract proof”, but may only be used after prior consultation for colour matching in the printing shop.

Is a proof on production paper possible?

“We are printing on a Berberich Allegro 135gr / sqm. Can you make a proof on this paper? “

In our telephone support, the question frequently arises. Unfortunately, we always have to answer the same. A contract proof on offset paper is technically not possible at the moment.

All Fogra certified proofing systems are currently based on an inkjet printers as proof printer, mostly from Epson, Canon or HP. These printers are characterized by a large colour gamut, good resolution and excellent homogeneity and colour stability – all the features that are essential for a proofing system. The Epson systems used by the overwhelming number of Proof printers are based on 11-colour pigment inks which have a significantly greater colour space than e.g. ISOCoatedV2 or PSOCoatedV3. The prerequisite for this is, however, the use of special papers optimized for waterbased inkjet printing, in which the pigments and inks are optimally applied. Special coatings are necessary for optimum reproduction, fast drying, good abrasion resistance and high UV stability of the print. On an traditional offset-printing paper without these coatings, the ink would run, hardly dry and would not be smudge-proof. Also the colour space would not be achievable. A proof would therefore not be possible from this point of view.

Can I check Moiré in the proof?

The moiré effect or, in other words, a halftone overlay is a common phenomenon in the view of prints. It appears when two unequal raster patterns overlap unevenly.

Moiré can not be tested in the Proof, as our proofs contain no screen patterns.

All standard proofing systems focus on the reproduction of colours, but not on the reproduction of the typical offset screen and offset rosette. Why?

Printers work with different screen widths and screen angles. From 54 to 80 screen in sheetfed offset up to 32 screen in the newspaper printing many screenings are on the market. The grid point is round, sometimes square, sometimes diamond-shaped. In addition, the screen angle of CMYK and spot colours from printing house to printing house is also different. And some printers also print a frequency-modulated screen, which is not subject to a screen angle, but is produced almost chaotic by the RIP. Because of this, proof-manufacturers mainly concentrate on the reproduction of colours, but not on screens and offset rosettes.

Detailed information can be found in our Proof Blog on www.proofing.de.

I need a proof for ALDI or Hofer with a verifiable GTIN / EAN code.

For Proofs for ALDI and Hofer, which have to contain a verifiable GTIN code, we have developed a special procedure, which can be used to ensure the verifiability of our proofed barcodes. We have summarized detailed explanations in an article on our blog:

Verifiability of GTIN codes for ALDI / Hofer in the Proof

For the conversion into verifiable GTIN codes we charge a flat rate of 10, – € plus VAT per GTIN code per file. If a barcode is shown on a product package on four pages, we will charge you 40, – € in addition to the Proof costs. If you need several Proofs of the same motif, the charges for exchanging the codes will be just only once. In the case of several motifs and several GTIN codes per motif, therefore, costs often exceed the costs of the Proof. The preparation of the codes is a manual effort, which requires time and effort and professional knowledge. We therefore ask for your understanding.

What proof standards are offered at Proof.de?

We proof all the latest proofing standards of the European Color Initative (ECI), IDEAlliance, Fogra, IFRA, JPMA and some older but still common profiles. Our proofs are measured in M0, new proofing standards also in M1 mode, taking the optical brightning agents into consideration.

Offset and NewsprintISO Coated v2 (ECI) / ISO Coated v2 300% (ECI) Standard for glossy and matte coated paper ISOUncoated Standard for uncoated white natural paper PSOCoatedV3 (Fogra 51) The successor of ISOCoatedV2 for glossy and matte coated paper with moderate optical brighteners PSOUncoatedV3 (Fogra52) The successor of PSOUncoated for uncoated, wood-free natural paper with many optical brighteners PSO Uncoated ISO12647 (ECI) The successor of ISOUncoated PSO LWC Improved (ECI) Improved LWC paper, glossy coated, successor of ISO Web Coated PSO LWC Standard (ECI) LWC paper standard, glossy coated ISO Web Coated LWC paper standard, glossy ISO Uncoated Yellowish Uncoated natural paper, slightly yellowish (chamois) SC Paper (ECI) Super calendered paper PSO SC-B Paper v3 SC-B Paper, Super calendered paper, satin-finished PSO MFC Paper (ECI) Machine finished coating paper PSO SNP Paper (ECI) Newsprint WAN-IFRAnewspaper 26v5 Newsprint ISONewspaper 26v5 Newsprint PSO Coated NPscreen ISO12647 (ECI) Glossy and matte coated paper PSO Coated 300% NPscreen ISO12647 (ECI) Glossy and matte coated paper PSO Uncoated NPscreen ISO12647 (ECI) Uncoated white natural paper Improved Newsprint, INP Commercial and specialty offset, INP paper (improved news print) PSO Coated v2 300% Glossy laminate (ECI) The profile is consistent with the old profiles ISOcoated_v2_eci.icc and ISOcoated_v2_300_eci.icc and shows the matching gloss finished result. PSO Coated v2 300% Matte laminate (ECI) The profile is consistent with the old profiles ISOcoated_v2_eci.icc and ISOcoated_v2_300_eci.icc and shows the matching matt-finished result. eciCMYK – CMYK exchange colour space FOGRA53 is a CMYK exchange colour space and is used for colour communication in print production. Heaven 42 (Scheufelen/Igepa Paper) ultra white natural paper (Heidelberger Druck) PaC.Space PaC.Space is the first common colour standard for packaging gravure printing, which enables to process an interface from the supplied prepress data or printer-specific requirements. |

RotogravureLWC Plus V2 M1 The successor of LWC Plus (PSR_LWC_PLUS_V2_PT.icc) LWC paper (light weight coated) LWC Plus The successor of HWC LWC Standard V2 M1 The successor of LWC Standard LWC Standard LWC paper (light weight coated) SC Plus V2 M1 The successor of SC Plus SC Plus whiter super calandered paper SC Standard V2 M1 The successor of SC Standard SC Standard super calandered paper PSR MF V2 M1 Rotogravure, paper type MF or INP News Plus (PSRgravureMF) PSRgravureMF is now referred to as News Plus US / International ProfilesGRACoL2006_Coated1v2 GRACol interpretation of ISO 12647-2,glossy and matt coated paper SWOP2006_Coated3v2 SWOP interpretation of ISO12647-2 for web offset printing on thin coated paper SWOP2006_Coated5v2 Other SWOP interpretation of ISO12647-2 for web offset printing on thin coated paper JapanColor2011Coated The new standard of Japan Printing Machinery Association (JPMA) Japan Color 2001 Coated Standard of Japan Printing Machinery Association (JPMA) SWOP 2013 C3 CGATS21-2-CRPC5 GRACoL 2013 Uncoated CGATS21-2-CPRC3 GRACoL 2013 CGATS21-2-CRPC6 |

You can find more detailed information on the Offset Printing Proof Standards, ICC profiles and the proof profiles used here or on our Proof-Blog at https://psocoated-v3.com/proof/proof-profiles/

Where can I download the ICC-profiles for proofs?

We have compiled for all of the available Proof profiles for download in our blog. You can find all information about Proof- and ICC-profiles and download the ICC profiles here: http://www.proof.de/proof/proof-profile/ Further information of the profiles, downloads and exact specifications can also be found on the websites of the respective organizations, such as: http://www.eci.org http://www.wan-ifra.org https://www.idealliance.org

There is no proof standard for my medium/ printing process.

It is always best to ask the respective printing house which standard they would recommend. In general, it can be said that many printing companies orientate themselves on the colourfulness of ISO coated v2, although this is actually only intended for sheet-fed offset on coated paper. This would then not be colour and legally binding for other printing processes and media, but at least suitable to communicate an expectation to the printing house.

I plan to print abroad. What profile should I choose for my proof?

Is it possible to proof without a profile?

Proofs are standardized products that are created and tested according to a certain set of colour values. This is precisely the point that distinguishes it from any other “coloured print”. A traditional proof for offset printing on image-printing paper is produced according to the standard values of ISOCoated V2 (paper type 1 and 2, glossy and matte coated imagery, tone value curves A (CMY) and B (K) from ISO 12647-2: 2004) (FOGRA39L). A Proof for uncoated paper (e.g., PSOUncoated) is manufactured and tested according to quite different values. Of course, because a print on a uncoated paper definitely looks different in terms of colour and paper whiteness than a print on coated paper. A proof therefore always has to be prepared according to a standard and be verifiable according to a reference value set. Unfortunately, a proof without a profile can not be produced, because that would be nothing but some “coloured paper from a proofing system”, but not a colour-binding, ISO-compliant proof. If you need to create a proof, but you do not have any details about the profile you need, then you should order a proof in ISOCoatedV2. This has become the most widely used standard in the industry and will therefore always be accepted as a basic proof. With the introduction of the new standards, Fogra 51 and Fogra 52, we also offer proofs in these proofing standards on OBA proofing papers. Please check with your printer whether or not they already print according to the new standards or still use the traditional standards and order your proofs accordingly. Our Heaven42 proofs are a special case. This is not an international standard, but a house standard by Scheufelen paper manufacturer, which simulates the print on the unusually high-white coated paper. These Proofs are therefore not legally binding in terms of ISO, but simulate within the tolerances the colour of the colour profile published by Scheufelen and Heidelberger Druck.

Can I proof spot colours like Pantone and HKS?

We use the proofing system with the most precise colour reproduction on the entire printing market. With our 11-colour proofing system we can proof spot colours such as Pantone and HKS colours better than many other service providers. In our proofing software we have stored all common colours so that spot colours are simulated as well as possible in the digital proof.

If our system does not know your colour, we can enter the colour manually. In this case we also try to achieve optimum reproduction. But one thing is clear: colours such as Pantone 811 or silver and gold can only be represented approximately.

The following colour systems are stored in our proof printer:

- HKS: HKS K, HKS N, HKS Z

- Pantone: Pantone C, Pantone U, Pantone Goe C, Pantone Goe U, Pantone M, Pantone TCX (Textile), Pantone TPX, Pantone DS

- Toyo

- DIC

Further compact information on the display of PANTONE and HKS colours can be found here.

Detailed information, image examples and colour deviation tables for all common PANTONE colours can be found on our blog Proofing.de:

› Can spot colours be proofed?

› How accurate can Pantone colours be reproduced in proofing?

› Colour deviations of Pantone colours in proofing in Delta-E (∆E)

› Colour deviations of Pantone Metallics and Pantone Premium Metallics colours in proofing in Delta-E (∆E)

I want to have Pantone or HKS colours proofed, what do I have to consider?

Pantone and HKS colours should be created as spot colours and correctly named.

Our RIP recognizes the colours by name and assigns the corresponding Lab values to the colours. Please note that, for example, different Lab values are assigned to a PANTONE 300 C (for coated paper) and a PANTONE 300 U (for uncoated paper). Our RIP would therefore also try to reproduce a spot colour for uncoated paper on a proof for coated paper.

However, in production printing, where physically mixed spot colours are used, this cannot be easily reproduced. There would be clear colour deviations between proof and production run.

If you would like to know in advance how well we can match your spot colour, please look here: https://shop.proof.de/en/info/PANTONE-and-HKS-proofing.html

Can metallic colours be proofed?

The underlying colour tone can be proofed, but there are no printers suitable for proofing that have metallic pigments. Unfortunately, it is therefore not possible to reproduce the metallic gloss in the proof.

PANTONE Premium Metallics or PANTONE Matching System Metallics?

At the moment there are two metallic colour fans in use at PANTONE:

PANTONE Metallics Coated: Contains the classic metallic colours already available since the end of the 1980s.

• Main base colours: PANTONE 877, 876, 875 …

• Typical colour names: PANTONE 8020, 8040, 8060 etc.

PANTONE Premium Metallics Coated: The new metallic colour compartments, which has existed since 2012, shows new, finer metallic colours.

• Main base colour: PANTONE Silver 10077 C

• Typical colour names: PANTONE 10142, 10158, 10214 etc.

The main differences between the two colour fans are the composition of their respective base colours: Firstly, the different Pantone Silver: PANTONE 877 or PANTONE Silver 10077 C. On the other hand the PANTONE Metallics Coated is supplemented by further gold base colours, while the PANTONE Premium Metallics Coated the newly defined silver is the only metallic base colour and is toned by other PANTONE base colours.

Detailed information about PANTONE Metallics can be found in our Proof Blog at www.proofing.de

How can I upload my proof data? Upload while ordering? Dropbox? WeTransfer? FTP?

We offer you an upload directly in our proof shop during the order, where you can upload up to 30 files with up to 420 MB per each article. Most customers use this way to upload their files. Your data is still available for about 1 year in the shop. If during our data check an error appear like RGB colours etc. you can easily delete your old data and upload new data. For us, this way is the easiest to handle your Proof data.

Sometimes, however, there are reasons for using another way, maybe very large files, uneasy proxy servers or simply the fact that you already have a WeTransfer link to the data but do not want to download it first and then upload it again.

We also download and process your data from WeTransfer, Dropbox or a direct link to your NAS system, your FTP or your web server. Such links or the access data for this you can simply write us in the messages field during the Proof order.

We can also provide customers who frequently orders their own FTP upload space.

What size should I use for my proofs?

From DIN A4 to DIN A1 we offer not only the DIN formats as DIN A4, but also a DIN A4+ format in oversize. The “+” formats are each about 2.5 cm higher and wider than the respective DIN formats. This has the following background:

The roll formats are mostly optimally adapted to DIN formats. Our most common roll width is 61 cm, perfectly suited for two transversal DIN A4 pages plus 3 mm side edge and 5 mm distance in the middle between the two A4 proofs.

If you now add crop marks and bleeds, the page size increases accordingly. If your page is instead of 297 mm by the cut marks 315 mm large, then we cannot fit two transwersal pages next to each other. The RIP then places the pages in the portrait format. We need to cut and discard some 170 mm of material. Therefore we calculate the DIN formats with marks and bleed at a small extra charge in order to calculate the higher material consumption.

our proofing formats:

| A6: | 105 x148 mm |

| A5: | 148 x 210 mm |

| A4: | 210 x 297 mm |

| A4+: | 235 x 320 mm |

| A3: | 297 x 420 mm |

| A3+: | 320 x 445 mm |

| A2: | 420 x 594 mm |

| A2+: | 445 x 620 mm |

| A1: | 594 x 840 mm |

| A1+: | 620 x 880 mm |

| 70/100: | 700 x 1000 mm |

| A0+: | 882 x 1247 mm |

How large will my data be proofed? Can you scale data?

We do not scale, add or omit anything. You receive your proof in exactly the same size as the data uploaded. If you have created crop marks in the PDF, they are also proofed. If you have not created any, we will not add any crop marks.

Is the proof cut exactly to size?

No. We proof from roll paper and not from exact DIN sheets. Your proof will usually have a white border several millimeters wide, but due to the roll format it can also be several centimeters wide. We cut by hand, therefore the cuts are not always 100% exact.

Do I have to take into account the space for the media wedge in my print data?

Media wedge, test report and job ticket (a few lines of text with details of the medium, printer, proof profile, etc.) are printed under or next to your motif. The space it takes up is added to your motif and does not have to be taken into account by you.

Do I have to apply bleed, crop marks or fiducial marks?

We do not need any bleed or printing marks of any kind. Basically we print 1:1 what is created in your print data. If you supply us with print data with bleed and crop marks, you will also receive a proof with bleed and crop marks. Please note that bleed and printer marks expand the format. So if you want us to proof an A4 with bleed and crop marks, you should not order A4, but A4+.

Can I also have a PDF with multiple pages proofed?

Yes, as long as the number and format of the pages in your print data match your order, it does not matter to us how many files these pages are distributed over. For example, combinations of a multi-page PDF and JPGs or Tiffs would also be possible.

Do I have to embed a colour profile in my print data?

As long as your print data contains only CMYK colours and perhaps spot colours (Pantone or HKS), it is not relevant for the proof what kind of colour profile is embedded in the file. Our RIP simulates the ordered profile using the existing CMYK values and Pantone or HKS colours according to Lab values stored in our RIP. Yet, correctly applied PDF/X3 and PDF/X4 also enable us to proof print data containing RGB colours with colour accuracy. For this, however, it is essential that the corresponding colour profiles are embedded for all elements and that the output profile also corresponds to the profile ordered.

How exactly do you handle CMYK colour profiles in PDF data? What happens in case of a CMYK “Profile Mismatch”?

When we receive a file from you, the first thing we do is ensure that there are no colours other than CMYK in the file. If the file is exclusively in CMYK, it will be sent directly to be proofed.

Dealing with wrong profiles with CMYK data / “Profile Mismatch

If we have received only CMYK data from you, we will ignore all input and output profiles contained and use only the CMYK values that we match to the ordered output colour space.

Example: Data in ISOCoated, proof ordered in ISOCoatedV2, meaning wrong or no CMYK profile embedded

You send a file with the profile ISOCoated and a colour area in CMYK 100/70/0/0 and order a proof according to ISOCoatedV2. We ignore the ISOCoated profile and proof the pure colour value 100/70/0/0 according to ISOCoatedV2.

Why do we do this? In our proofs we try to reflect the “real life” of the print as good as possible. In many conversations with printing houses we have seen that in almost 100% of the cases they do not carry out profile conversions from CMYK to CMYK, but instead transfer a colour value of 100/70/0/0 to the plate, insert the paper and print in conformity with the standard without observing CMYK profiles. Thus we also map this way, although it would actually be “more correct” to carry out a colour space transfer from ISOCoated 100/70/0/0 to ISOCoatedV2. However, this results in a different colour value, for example 100/63/1/6 with relative colourimetric conversion with depth compensation or perceptive with depth compensation 100/63/3/15 !

Practical case: A customer of ours did not proof at our company, but at a colleague’s company 30 slightly different, dark blue colour fields in ISOCoatedV2, under which the CMYK value was written in black in order to colour match a powder-coated surface. The customer defined a very well fitting CMYK colour value on the basis of the proofed colour areas, inserted it in his brochures and started the print jobs.

The result: the dark blue was a clearly different blue than on the reference proof, the customer and the agency were very dissatisfied and went on a search for errors.

Now the case came to us. We received a file for the proof according to ISOCoatedV2 and compared it with the proof of our colleague. The colours with the same black CMYK values printed underneath were clearly different, but both proofs were provided with a media wedge and measured correctly. After some troubleshooting, we came up with the idea of requesting the original proofed file from our colleague, which still existed. This file contained a Fogra27Coated profile, i.e. a conversion of the old ISOCoated. A proof according to ISOCoatedV2 had been ordered at that time.

What had happened? The colleague had taken the input profiles into account, whereby a significant change in the CMYK values of the colour fields, as mentioned above, was accompanied by a colour space transfer from CMYK to CMYK. But the black printed CMYK values under the colour fields had of course not changed. So the CMYK value that had been sampled no longer corresponded to the proofed value at all. Our customer was up in the air: “What do you mean that our CMYK values were not proofed?”

With us this case would not have occurred, because we would ignore the embedded profile in CMYK data. In this case, this would also have been the expectation of our customer. After just under two hours, we had thus determined the “error” (or perhaps rather: the “difference”), provided our customer with a proof “in line with expectations”, on the basis of which he could determine the appropriate CMYK value in ISOCoatedV2, and had solved the problem.

How exactly do you handle RGB colour profiles in PDF data?

If we receive a PDF file that contains RGB images, the next step is to check whether the file is a valid PDF/X-3 or PDF/X-4. If this is the case, and all input RGB profiles are correctly labelled with colour space (sRGB / AdobeRGB / ECI-RGB-V2 etc.), then we check whether the correct output colour space has been used as output intent and whether CMYK data also contained in the file has the correct input profiles. If so, we proof the file with the settings: “Consider all input and output colour spaces”.

If RGB data should not contain a profile, e.g. if they are created in Device-RGB, we generate a “data not correct” email in which we explain our procedure as follows:

“Dear customer,

the data check has revealed that your data contains RGB elements. RGB elements can only be reliably interpreted in the proof if they are marked with a colour profile and a rendering intent. This is the case with correct PDF/X-3 and PDF/X-4 data, for example. The correct output intent must also be specified.

At least one of these criteria does not appear to be the case with your file.

The safest way would be to convert the contained RGB data to CMYK. This has the advantage that you have control over the conversion and can view the CMYK result in Acrobat before you upload the file again for proofing. We can then reliably use your CMYK values for the proof. To do this, call up the current order in your customer account, delete the incorrect data and upload thIf, for example, the RGB element should only be a small image that is not relevant for the overall impression of the proof, or if you do not have any other file available for the proof, then we can of course also use your RGB data for the proof. If available, we will use your RGB source profiles and rendering intents, otherwise we will use the sRGB standard and the rendering intent “elatively colorimetric with depth compensation”, which will lead to correct proof results in most cases.

If you would like us to proof the supplied RGB data in this way, please let us know. Please do not hesitate to contact us if you have any further questions.

Best regards, your Proof Team”.

What type of payment is the best? Can I order as a new customer on invoice?

If we could choose the way our customers pay, we would prefer the following payment options:

1 . SOFORT Banking (low fees for us, secure payment method, fast transfer to our bank account)

2 . Payment by invoice (no fees, but sometimes we must remind customers of a payment)

3 . Credit card or direct debit (all is billed via and costs us appreciably higher charges than for example with SOFORT Banking)

We send all Proofs immediately, also with payment by invoice, even for new customers, therefore there is no advance payment in our shop. We trust that our customers value our service and therefore also gladly pay our bills.

Where can I find the invoice to my order?

If you log in to our shop and select your account, you will see an overview of your previous orders. You can view and download the invoice directly in the overview.

10x the same page or ten different pages once. Does this cost differently?

Whether you have the same image 10x for proofing, or need 10 different images one each, that is no matter for us. If you need 10 pages DIN A4 size in ISOCoatedV2, then you can upload one PDF file with 1 page, which we should proof 10 times. Or a PDF with 10 different pages for proofing one page each. Or a JPEG, two TIFFS, a ZIP file with four one-page PDF and a PDF with three pages in it. As long as we can see 10 pages in the end, this is absolutely perfect. If you would like to have 10 copies of one page, please write us a short message in the messages field when ordering, otherwise we do not know exactly if you have just forgotten or overlooked pages during the upload.

I order from Austria or another EU country. Can I get an invoice without VAT?

For deliveries to EU countries, so-called intra-Community deliveries, you must provide us with your sales tax identification number during your order. We will then send you an invoice without German VAT. For the German tax office, however, it is important that we verify with your VAT number, and document the border crossing of the shipment to your country using the tracking protocol. Only under these two conditions can we issue a bill exempt from VAT.

For Switzerland and other third countries only the border crossing has to be proved. We do not need a sales tax ID in this case, the shop automatically generates an invoice without German sales tax.

Can I choose on which paper the proof is printed?

You cannot choose which paper we use for your proof. Which paper we use depends on the proof profile you have selected. We use a total of 4 different papers for our proofs. One each of coated and uncoated paper without optical brighteners and with optical brighteners. Basically, we always use uncoated paper for profiles intended for uncoated paper and coated paper for profiles intended for coated paper.

When we use which paper, you can also read under “Proofing Papers”.

I would like to have a design proofed several times. How do I proceed?

If, for example, we receive an order for two proofs but only one page has been uploaded, we will usually contact you to check whether you need the same design more than once or whether print data is still missing. In order to avoid a possible delay, you can tell us – preferably via the comment field – what we should proof and how often.

I made a mistake in my order. Now what?

Please contact us as soon as possible. The best way is via chat or by calling +49 (0) 7071-7952740. We can change or cancel orders afterwards, but the production of your proofs can sometimes start right after the order is completed. Therefore speed is of the essence.

I have uploaded new data, but the order status still says “data not correct”/ “data missing“

The status of our order does not change automatically, but must be changed manually by a member of the team. If you have recently uploaded new data, it may well be that no one has yet had a chance to look at the new data. If your data is still missing or incorrect, we would contact you again. Either by email or telephonically.

The proof is faulty. What now?

Please contact us! The best way to do so is via chat or by calling +49 (0) 7071-7952740. Despite all our efforts, it can unfortunately still happen that the proof software has a bad day and prints faultily, or we, being only human, accidentally get the wrong workflow or overlook fine stripes on the proof in the hectic rush of shipping. In such a case we will immediately produce new proofs and send them out again.

How well protected are the Proofs for shipping?

We ship up to the format DIN A4+ in a 400 gr/m2 chromosulphate cardboard sleeve with tear-open tab, from format DIN A3 and larger in a cardboard box, which is also provided with a tear-open tab.

The proofs are additionally inserted into polyethylene protective covers. As a result, the proofs are optimally protected during shipping by rain, moisture and climate influences. The protective covers are tear- and water-resistant and can be reused several times. You can send the proofs to your customer in the same protective envelope without any problems after review. Polyethylene foils burn without residue and without toxic fumes, gases and slags and are groundwater neutral.

The cardboard sleeve is also reusable, only the tear-open tab does not work any longer.

Only a few times a year do we receive a report that our packaging has been broken or damaged during shipping. This was a more frequent problem, especially with the envelopes, before the current chromosulfate cardboard solution.

We are also happy to send the proofs neutrally; Please notify us in the message box during the order process.

Can you also send proofs neutrally?

We would also be pleased to send your proofs neutrally. Please write us your wish for neutral shipping in the comments field during the order process. Our proofs are generally completely neutral and do not contain any reference to Proof.de. Your customer can therefore not trace who produced your proofs.

In the case of neutral shipping, you will receive your proof invoice by email.

We can also offer you this: Upload your delivery note as an additional file to your proof data. We will then print your delivery note in black and white and enclose it with your order. In other words: You order 10 pages of proofs in DIN A4 to be sent directly to your customer.

• Add 10 pages DIN A4 to the shopping cart and check out with customer delivery address

• In the comments field: “Please send neutrally, own delivery note will be uploaded” or write like this

• Upload two files: 1x “proofs” and 1x “delivery note” or something similar 🙂

• Complete the order.

Is it possible to ship to several addresses within one order?

For example, if you want us to proof all proofs twice and then send one set to you and one set to your customer, you can either place two orders, or write your request and the second delivery address in the comment field. We will then adjust the invoice to 2x shipping, and include it in your shipment.

Important: Do not pay by Paypal or bank transfer, but choose ” invoice” as payment method, because then the amount on the order confirmation does not correspond with the final invoice amount, and Paypal would therefore request the wrong amount from you.

Where can I find the tracking number to my order?

For packages whose shipping label we have created via our shop software, you will receive a tracking link via email. For proofs up to a maximum of A4+, we send the standard dispatch as Großbrief Prio with the Deutsche Post. We can see the tracking for this from our site, but it usually only tells us whether the parcel has already been delivered or not. The tracking for neutrally shipped parcels, DHL Express before 9 am and Express with Saturday delivery, can only be viewed from our site, as we generate the labels for these outside our shop software. However, if you contact us, we can find the corresponding link for you.

If I order now, when will the proof arrive?

Everything that we receive by 04.00 p.m. will be dispatched on the same day, provided that the order is completed on time and the print data are suitable for proofing. If you choose one of our express shipping options, the proof is quite reliably at its destination within Germany on the next working day. In standard shipping, it can also sometimes take a few days until delivery, which we cannot accelerate afterwards.

You can read more detailed information on this under “Shipping and Returns”.

The proof did not arrive / arrived damaged. What to do?

Please get in touch with us immediately, preferably via chat or by calling +49 (0) 7071-7952740. Despite our good packaging, it can still happen that the package and its contents are damaged in transit and the proofs arrive at your premises with creases. Even if the delivery is beyond our control, we will immediately prepare new proofs and send them to you again. For security reasons, please send us a picture of the creased proof and / or the creased packaging and do not throw them away. Although a complaint with DHL or UPS is usually not successful for us, we can at least try.

Thanks a lot.